Empresas participantes: Airbus Operations SL (Líder), Altran Innovación SA, Compañía Española de Sistemas Aeronáuticos SAU, Alava Ingenieros SA y Airgrup.

El proyecto ESCAPHIB tiene como objetivo último la investigación de cuatro nuevos bloques clave de la tecnología eléctrica que serán probados en un demostrador de avión híbrido (E-FAN X) desarrollado por el Grupo Airbus.

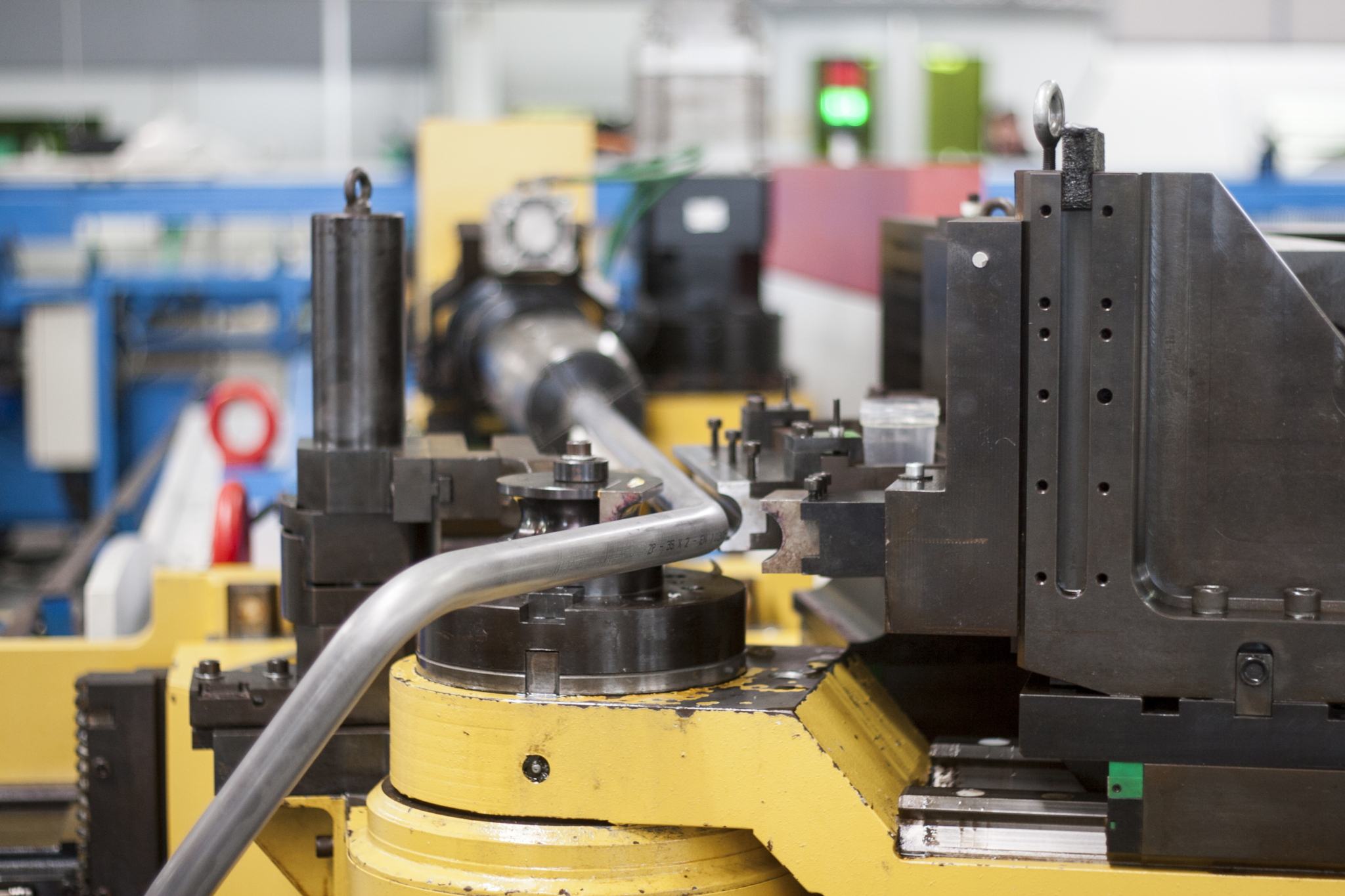

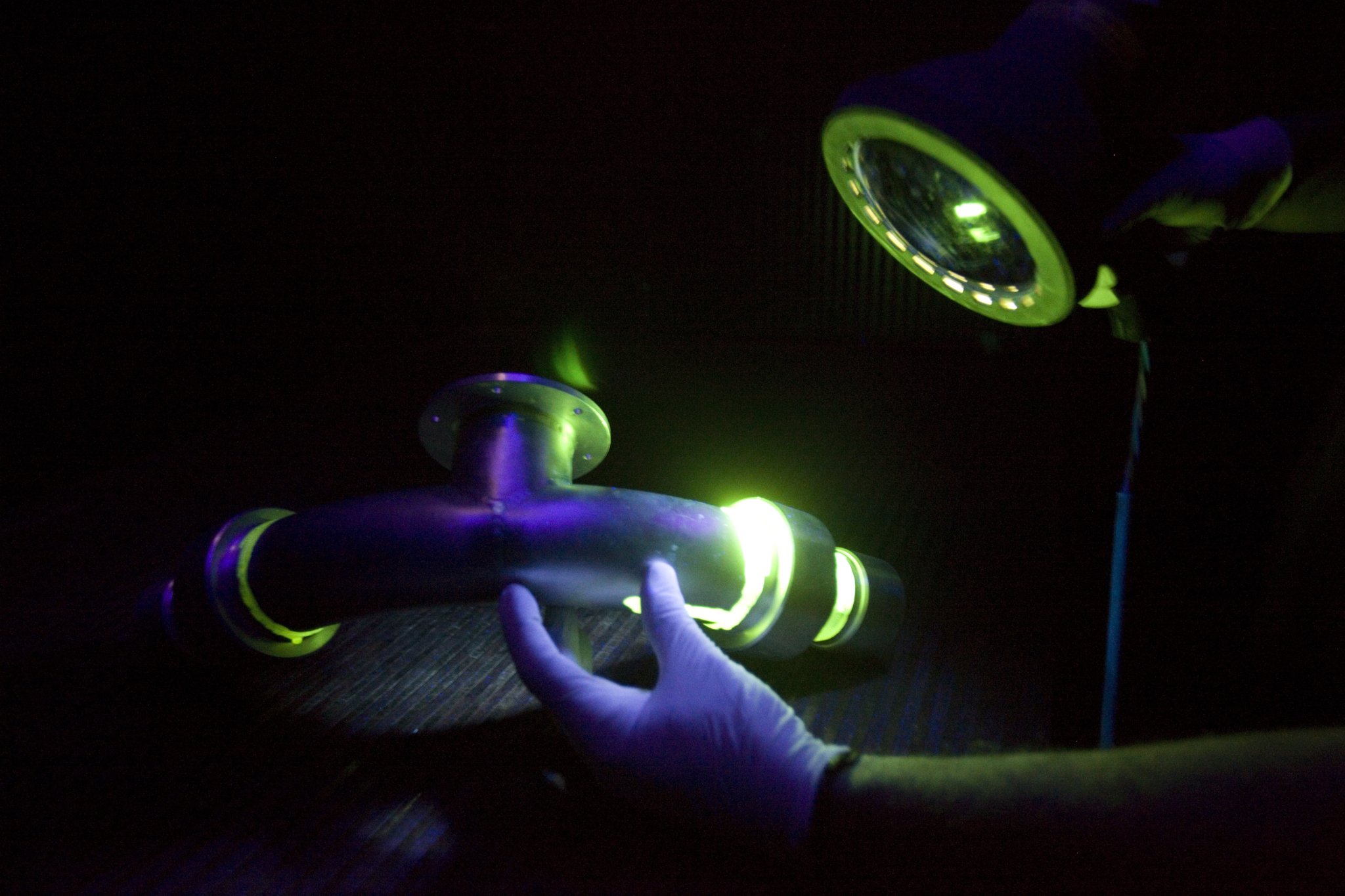

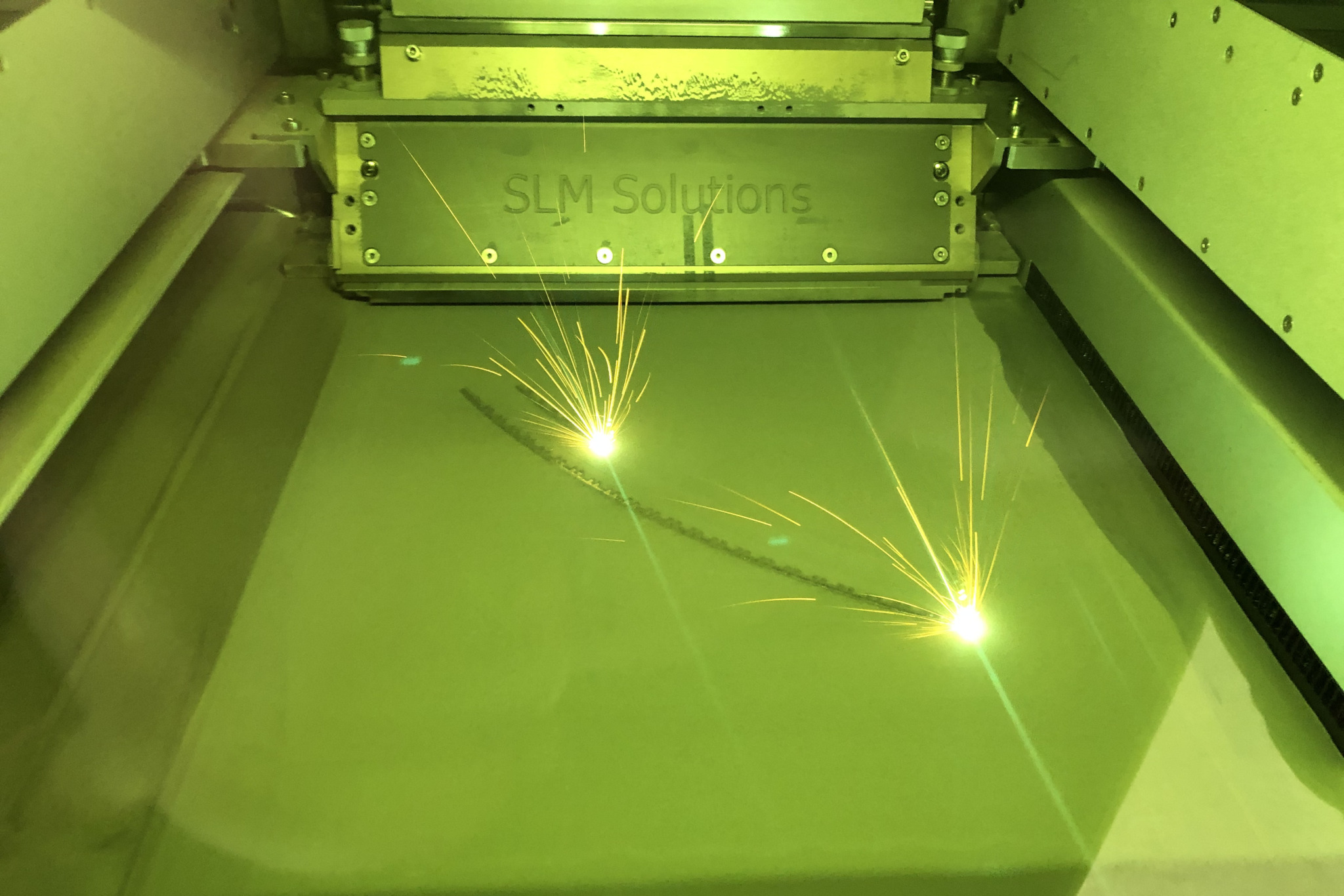

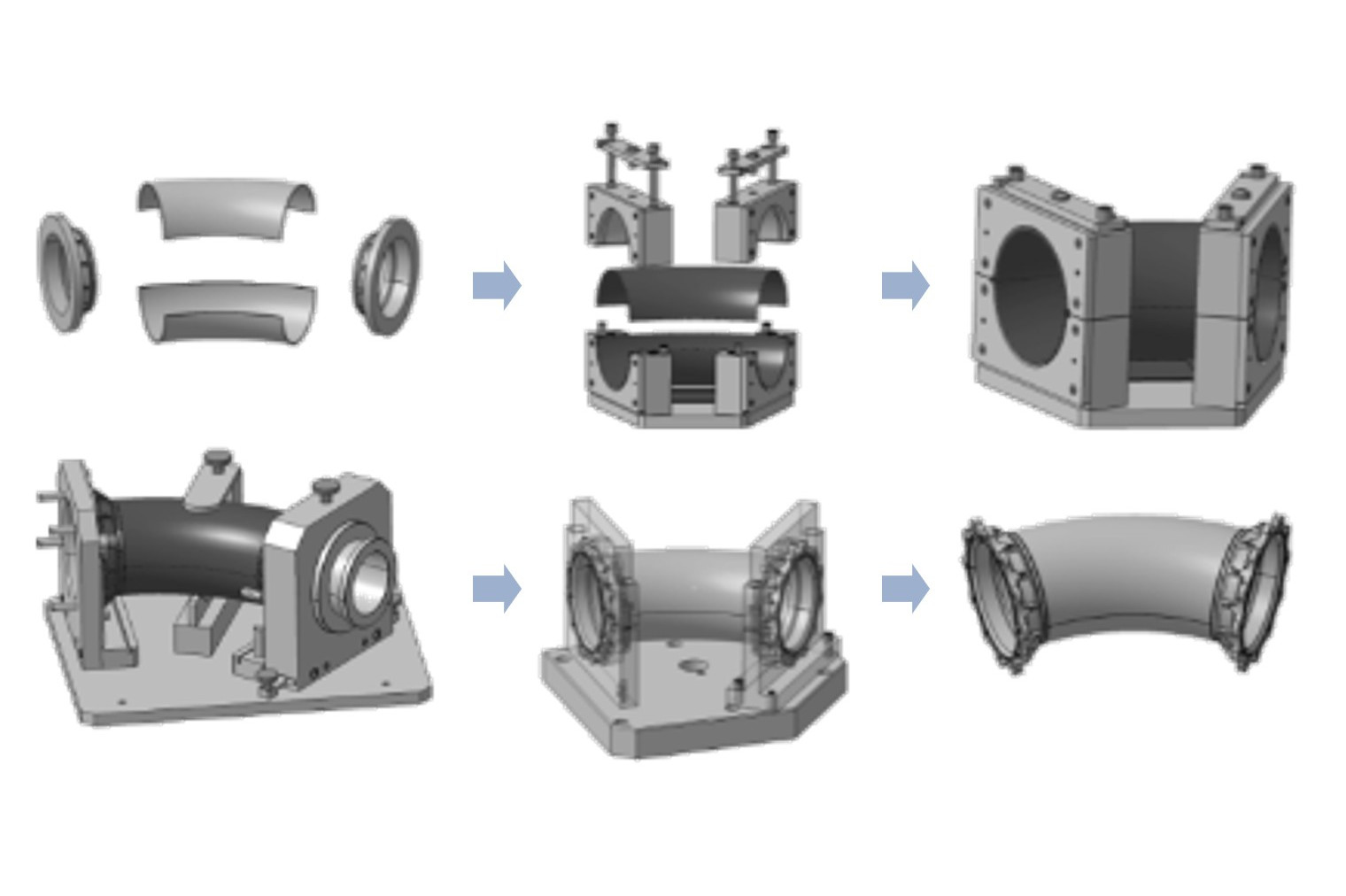

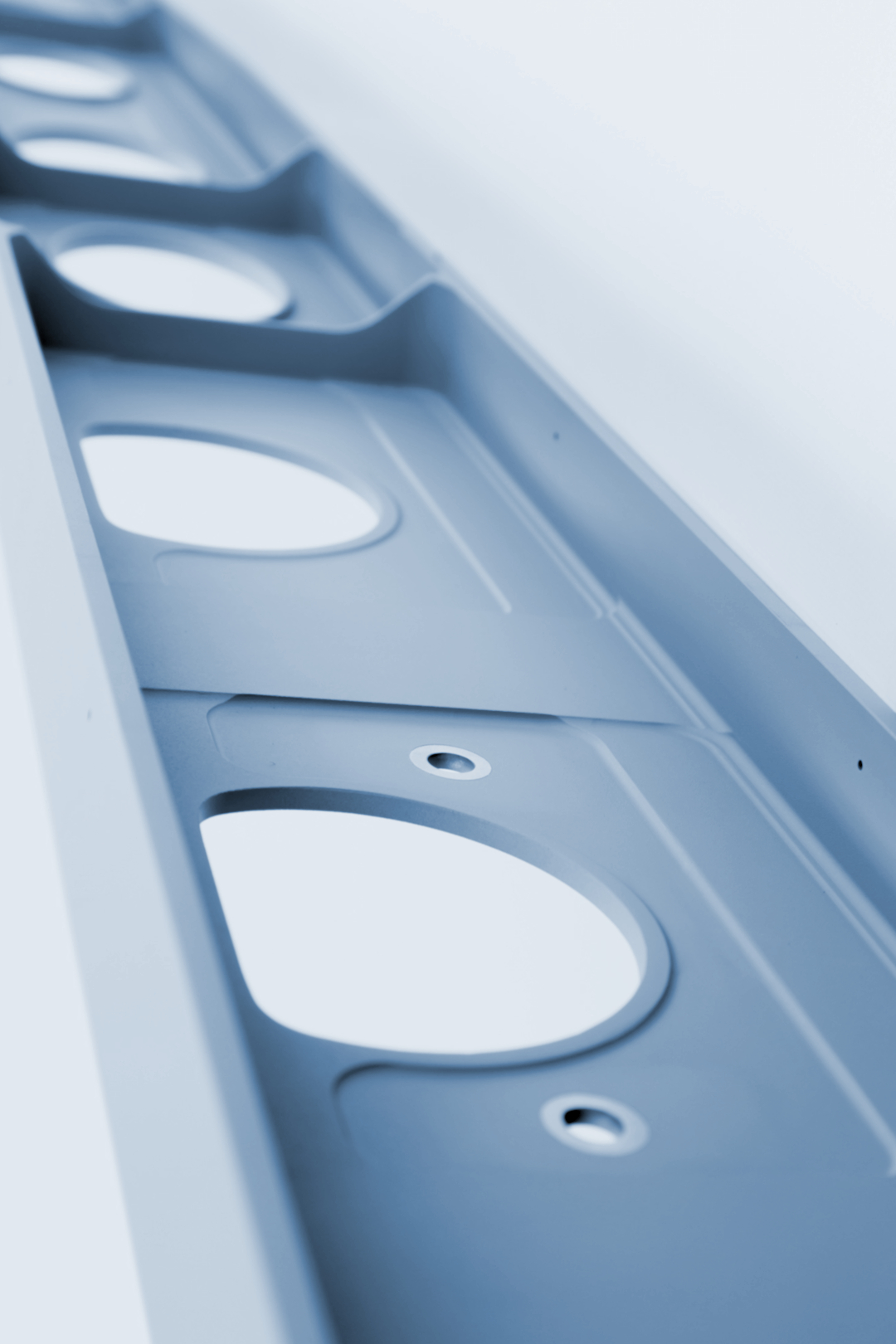

Estos nuevos bloques a desarrollar se centrarán, en concreto, en el sistema de refrigeración de alta potencia, la toma y el escape de un sistema de generación de alta potencia, el sistema de protección de baterías y el desarrollo de nuevas configuraciones en conos de cola, llegando a la validación y verificación de estos sistemas en tierra y algunos en vuelo.

El proyecto tiene una duración de tres años y medio, a ejecutarse entre 2018 y 2022 y se desarrolla con el soporte de varios organismos de investigación y centros tecnológicos.